Box Truck And Box Van Basics: A Simple Guide

Box Truck And Box Van Basics: A Simple Guide

Out of all the work trucks on the market, box trucks for sale or box vans for sale are the ideal vehicles for transporting cargo that exceeds a cargo van's capacity. It is now more critical than ever to know exactly how these delivery machines can help you serve your customers faster, safer, and in a manner worthy of many positive reviews.

What is a Box Truck or Box Van?

Box trucks and vans are versatile vehicles fitted with large, enclosed cargo areas with a flat floor and vertical sides. This design makes it ideal for securely transporting goods, equipment, and supplies. Box trucks are commonly used by businesses, movers, and delivery companies due to their ability to handle various types of cargo. Box trucks and vans are available in light, medium, and heavy-duty configurations and can be tailored to meet the specific needs of different industries. Whether you’re looking for a small truck for local deliveries or a larger one for long-haul transportation, there’s a box truck to fit your requirements.

Critical Box Truck Features

Dimensions

The generous dimensions of the box truck accommodate multiple pallets, numerous boxes, and even bulky furniture, which can fit perfectly within the box truck cargo bay. Ranging in length from 10’ to 28’ and with an interior height ranging from 6’ to 8' +, the box truck is ideal for any business's oversize product delivery needs. When your search turns to box trucks for sale, make sure to investigate the following critical features.

Floor Material

Standard flooring choices include pine or hardwood flooring. These create a slip-free, final staging area to ensure that your product is not damaged in transport.  The floor construction allows smooth pallet jack operation, supporting safe transfer between your loading area, the box truck, and the product’s final destination.

The floor construction allows smooth pallet jack operation, supporting safe transfer between your loading area, the box truck, and the product’s final destination.

Wall Material

Box truck walls are typically constructed with a focus on durability and lightweight design. The most common material is a fiberglass reinforced panel (FRP), which offers a good balance of strength, weather resistance, and affordability. Aluminum is another popular choice, valued for its lightweight nature and corrosion resistance, making it particularly suitable for refrigerated trucks. For applications requiring enhanced insulation, walls may be constructed with composite panels that sandwich a layer of insulation between aluminum or FRP sheets. This construction helps maintain internal temperatures and improves energy efficiency for climate-controlled cargo. Regardless of the material, box truck walls are designed to withstand the rigors of the road while providing secure and protected cargo space.

Roof Material

The box truck’s rugged walls are topped off with a reliable, weatherproof roof. Aluminum is a commonly used material boasting a tensile strength comparable to steel that reduces weight and adds a component of corrosion resistance.

Some models incorporate a semi-transparent fiberglass panel to their box truck roofs to provide lighting during daytime loading.

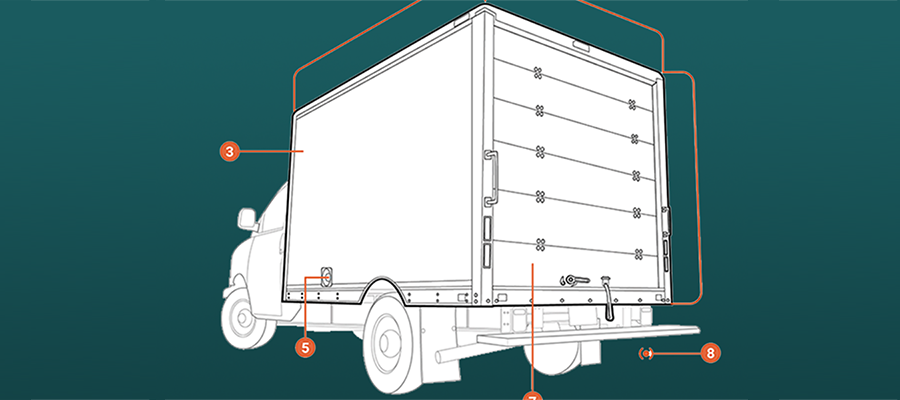

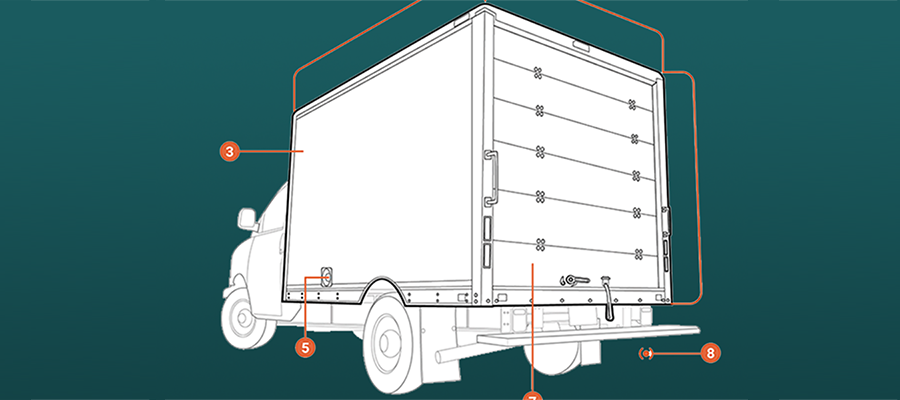

Critical box features of a box truck

Fuel

Constant interruptions for refueling or recharging can be a major disruption to efficient delivery operations. Recognizing this, vehicle manufacturers have prioritized equipping their delivery trucks with higher-capacity fuel tanks and extended-range batteries for electric models. This focus on maximizing fuel and battery capacity aims to alleviate concerns about frequent refueling or charging stops and keep delivery routes running smoothly, regardless of the powertrain technology.

Inside Sliding Door

Box truck manufacturers have come a long way since the early days of delivery management. You no longer need to make a long-winded pit stop just to inspect the cargo bay. Now, an easy-access sliding door between the cab and cargo bay makes diagnosing the “bumps” and “bangs” resulting from traffic and shifting products en route an entirely quick and painless process.

Rear Door Styles

Box trucks offer various rear door options to suit different needs and cargo types. The most common type is the roll-up door, made from durable, lightweight aluminum, which offers convenient access and maximum opening height.

For heavier-duty applications, swing doors are available, often constructed from reinforced steel or FRPs. FRP offers a combination of strength, durability, and lighter weight than traditional steel, making it a popular choice. These are ideal for loading with forklifts and pallet jacks. Some trucks may also feature combination doors that blend a roll-up door with a smaller swing door for separate access to smaller items. Regardless of the chosen configuration, rear doors typically incorporate features like robust locking mechanisms and weather seals to protect cargo from theft and the elements.

Side-Access Cargo Doors

Set into either side of the box truck’s cargo hold, these swing-open or roll-open side doors allow easy access to all corners of the box truck’s cargo area. The side doors feature customization in single rolling doors, or single and multi-panel arrangements of steel, aluminum alloy, or FRP configurations. Both styles fully support a series of locking mechanisms, to ensure that easy access doesn’t mean easy theft.

Liftgate

For deliveries requiring heavy cargo to be offloaded without loading docks or extra hands, a gate lift becomes an indispensable tool for your box truck. Liftgates provide a powered platform to raise and lower goods from the truck bed to the ground, reducing manual labor and the risk of injury. Several options are available depending on the application. Rail gates are a common choice, offering a sturdy platform that slides along rails for vertical movement. Tuckunder gates fold up and store beneath the truck bed when not in use, maximizing cargo space. For heavier loads, column liftgates provide higher weight capacities and increased stability. Liftgates are commonly made from steel (for affordability and strength) or aluminum (for lighter weight and corrosion resistance). The best choice depends on your budget, load capacity needs, and priorities regarding weight savings and maintenance.

Box Truck Uses

Box trucks are incredibly versatile and can be used for a variety of purposes:

- Moving and Relocation: Moving companies often rely on box trucks to transport household goods and equipment. Their spacious cargo area and secure design make them ideal for this purpose.

- Delivery and Transportation: Delivery companies use box trucks to transport goods and supplies to customers. The enclosed cargo area protects items from the elements and ensures they arrive in good condition.

- Commercial Applications: Businesses use box trucks to transport equipment, supplies, and goods. Whether it’s for retail, wholesale, or service industries, box trucks provide a reliable transportation solution.

- Construction and Landscaping: Construction and landscaping companies use box trucks to transport equipment and supplies to job sites. Their durability and capacity make them well-suited for these demanding tasks.

Overall, box trucks are an essential part of many industries, offering a reliable and efficient way to transport a wide range of items. Whether you’re moving, delivering, or transporting goods, a box truck can help you get the job done. If your business is in need of a commercial truck, check out our box trucks for sale or explore our rollback trucks for sale to find a reliable and vehicle near you.

UPDATED ON: NOVEMBER 22, 2024

Published on: January 01, 2018